CounterFlow Deaerator

- Inability to deliver .007 ppb outlet quality in applications with a low inlet water temperature, or when 100% make-up is required

- Low tray loading. This reduces the flow rating for a given diameter deaerator vs a parallel downflow unit

- High vent rate. This reduces operating efficiency

- The counterflow deaerator is cheaper to manufacture

Parallel Downflow

- More complicated design, resulting in slightly higher cost

- Time proven design

- Thousands of installations worldwide

- Design suitable for small to medium plants

- Can meet ouutlet guarantees in higher outlet capacity for any given diameter

- Large tray spilling edge, resulting in high deaerating efficiency

- Low vent rate, resulting in increased operating efficiency

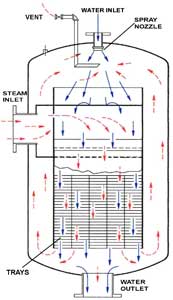

Parallel Downflow Operation

In this design, the inlet water is sprayed into a steam atmosphere through variable orifice, spring loaded spray nozzle(s). This action heats the water to within 2 to 3 degrees of the steam temperature, while liberating 90% to 95% of the dissolved gases.

This pre-heated, partially departed water then flows down through a water seal(s) for distribution over the tray bank. The water seal(s) serve two functions. First they prevent gases liberated in the initiate heating, from entering the tray bank. Second they direct the steam to flow down through the trays, before entering the upper heating section.

The main function of the tray bank is to remove the remaining amounts of dissolved gases, not liberated in the initial heating. Since very little, or no heating takes place in the trays, the entire volume of steam is used to scrub out the remaining gases. The trays are slotted, and provide a great amount of spilling edge. This allows for a great amount of water surface area to be exposed to the steam. Water flows downward through the trays. Steam flows downward through the trays. Thus the name parallel downflow.

The steam, after exiting the tray bank, then flows upward into the top of the deaerator where it is used to heat the incoming water being discharged by the spray nozzles. The steam is condensed by the colder inlet water, and a small amount is vented to atmosphere, along with the dissolved gases.

The deaerated water flows from the deaerator down into the storage tank. The stored water is covered by a steam blanket, to maintain heat, pressure, and prevent recontamination of the deaerated water.