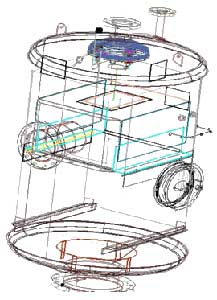

The deaerator shall be of the parallel down flow (co-flow) type, designed for oxygen removal of .005 cc/l (7ppb) and complete carbon dioxide removal, when operated at design conditions. The deaerator is to be designed to handle 100% cold make-up water, and varying plant loads from 10% to 100% of its design capacity. The deaerator is to be of vertical design, and flange mounted to a horizontal storage tank. Both pressure vessels are to be manufactured and stamped in accordance with the ASME Code for unfired pressure vessels, Section VIII, Division 1.

The deaerator and storage tank are to be shipped separately.

The internal direct contact vent condenser, consisting of spray nozzle(s) and vent piping, is to be manufactured out of 304 Stainless Steel. Water entering the deaerator will be sprayed into a steam atmosphere using a spring loaded spray nozzle(s), capable of providing a large exposed surface area of water to steam. The spray nozzle shall be manufactured from 304 Stainless Steel, and incorporate a solid teflon spreader, to eliminate metal to metal contact, and insure long operating life.

Each deaerating tray is to be formed and stamped from a single piece of 430 Stainless Steel. Each tray is to have interlocking tabs to insure staggered slot installation

The deaerator shall be designed so that the direct contact vent condenser and the internal design prevent noncondensible gases and undeaerated water from coming in contact with the pressure vessel shell.

The deaerator is to have a minimum 14″ x 18″ manway opening for tray installation, and internal inspection. All necessary connections for instrumentation and level indication/control are to be included in the deaerator and storage tank design. The storage tank deaerated water outlet connection is to be equipped with a vortex breaker capable of preventing feed pump cavitation.